1. Product Overview

This product complies with the technical standards of the International Basketball Federation (FIBA) and has obtained FIBA certification. The company has decades of experience in the production and manufacturing of sports equipment. The company has introduced advanced manufacturing and processing equipment to make each series of products have a perfect appearance.

The company has passed ISO9001:2000 quality system certification and ISO14001 environmental management system certification. All products of the company are provided with quality insurance by the People's Insurance Company of China. Our products have been continuously rated as qualified products by the National Sports Goods Supervision and Inspection Center, named as famous and excellent products by the Provincial Technical Supervision Bureau, and awarded as a consumer trustworthy unit by the Consumer Association. The product is highly praised by users from colleges and universities, sports bureaus, and military cultural stations. This product is a product you can trust.

2. Main structure

1. Technical specifications

The basketball stand has an arm extension of 2.35m, the upper edge of the basketball ring is 3.05m above the ground, and the box size: length × width × front height × rear height = 2.0 × 1.0 × 0.82 × 0.42 (m). The product meets the technical requirements of the International Basketball Federation. The basketball stand is suitable for a venue of 37.5 meters.

2. Product materials

The box is welded with δ2.5mm steel plate, the front arm is welded with 60×120×2.5mm rectangular tube, the extension arm is welded with 150×150×3mm square tube and δ3mm steel plate, the upper pull rod is φ48×2.5mm welded tube, and the rear pull rod is 60×80×2.5mm rectangular tube. The box base is cast steel, and the weld surface is uniform and smooth. The backboard ears are made of precision aluminum alloy, using die-casting technology, with beautiful appearance and reliable performance.

3. Backboard

The backboard is made of high-strength safety glass backboard (12mm thick tempered glass), specification: 1800×1050 (mm), with high transparency, good weather resistance, anti-aging, corrosion resistance, and not easy to blur. The tempered glass is affixed with explosion-proof film to ensure the integrity of the tempered glass after breaking, thereby ensuring the personal safety of the athletes. And the bottom edge and side of the backboard are covered with EVA polyester strips to protect athletes from injury when dunking. The height and thickness of the front and rear surfaces of the protection ring are ≥20mm, and the bottom thickness is ≥50mm. The screw holes on the rubber strip are covered with special plugs, which have a beautiful appearance and protect the athlete's fingers. In accordance with FIBA rules, the backboard elasticity is 500N/min, the center deflection is ≤6mm, and the backboard returns to its original state after the external force is removed for 1min.

4. Basket

The basket ring is made of φ20mm round steel, which has good bending resistance. There is a stamped arc-shaped net hook welded under the ring. The twelve sections are evenly distributed with appropriate gaps. The net is fixed with elastic nylon rope, which is easy to install and replace. When a static load of 105kg is applied to the top of the farthest point of the basket ring, the downward rotation angle of the basket ring is not less than 10 degrees and not more than 30 degrees, which can ensure the stability of the basket ring when the athlete shoots and the safety when dunking.

5. Protective measures

The rear of the basketball stand is equipped with a special counterweight, with a single counterweight of 420kg, to ensure that the basketball stand does not tip over when a static load of 3200N is applied to the root of the basket ring. A special insurance mechanism is installed between the front arm and the extension arm to effectively ensure the safety and stability during use.

6. Fasteners

All fasteners are treated with Dacromet plating to ensure that they will not rust all year round.

7. Surface treatment

All steel parts are treated with degreasing and physical rust removal (shot blasting) before being sprayed with electrostatic epoxy powder on the spray line for the final surface treatment. The coating thickness is 90-110um and the pencil hardness is 3H+. The test product has been tested by GB1771-91 for 36 hours. The coating film has no change, and the single-sided corrosion at the grid is less than 2mm. The product has the advantages of acid and alkali resistance, heat and humidity resistance, aging resistance, and beautiful appearance. It can be suitable for humid and acid rain environments, and the product coating has been inspected and qualified by the National Sports Goods Quality Supervision and Inspection Center, and the formula does not contain harmful substances.

III. Installation and commissioning

I. Before installation, remove all packaging.

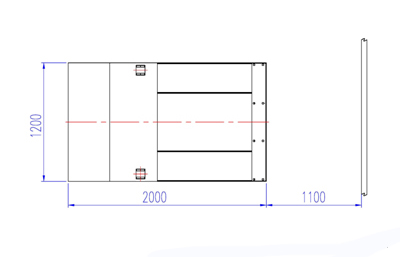

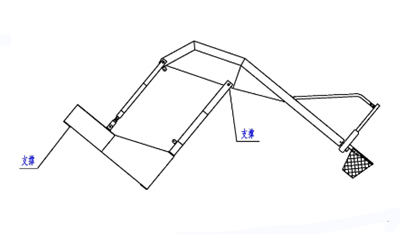

1. Place the basketball stand box so that the front edge of the box is 1.1 meters away from the outside of the sideline of the field (the center of the box is facing the center of the court). (See Figure 1)

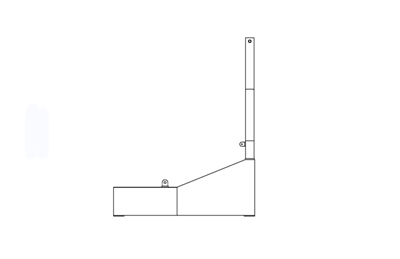

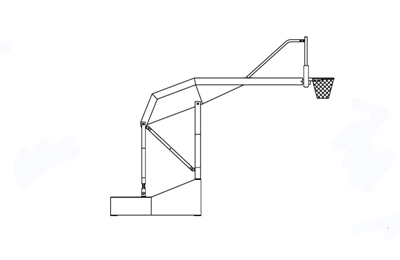

2. Fix the column to the box flange with M18X45 bolts, leveling washers and spring washers. (See Figure 2)

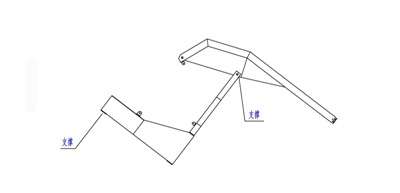

3. Tilt the basket rack, support it with a hard object, and firmly connect the column and the arm with the shaft. (See Figure 3)

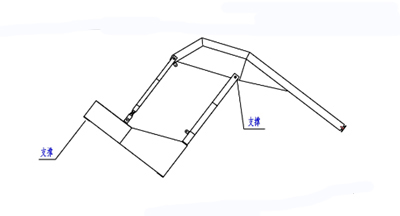

4. Install the rear tie rod, and firmly connect the rear tie rod to the box ear with the special tie rod bolt (M28) and nut. Use the shaft to firmly connect the rear end of the arm. (See Figure 4)

5. Use the Ω pressure plate and M10X25 bolts to fix the upper tie rod to the arm, and then use the M12X35 hexagon socket screw to connect the upper tie rod to the backboard ear, and connect the basketball hoop to the backboard with M10X80 bolts, nuts, flat washers, and spring washers. (See Figure 5)

6. Tighten all the bolts and nuts of the basketball rack. Slowly level the basketball rack, install the locking rod, put in the counterweight, and the basketball rack is installed. (See Figure 6)

II. Debugging

1. Parallelism of the lower edge of the backboard

Loosen the connecting bolts between the basket ring assembly and the outrigger, loosen the locking rod, level the backboard, and level the basket ring and tighten it at the same time, so that the vertical height between the upper edge of the basket ring and the ground is 3050mm. (The height of the basket can be adjusted by adjusting the rear tie rod bolt), and finally install the locking rod and lock it.

2. Verticality of the backboard

Adjustment of the verticality of the backboard and the plane of the field: moderately loosen the connecting bolts between the upper tie rod and the pressure plate, adjust the verticality of the backboard by adjusting the front end adjustment piece of the outrigger, and then tighten the bolts.

图1

图2

图4

图4

图5

图6

IV. Precautions

1. It is forbidden to hang the basket, climb the frame, and hang extra heavy objects.

2. Regularly check the fastening parts of the basketball bolts. If they are loose, tighten them immediately or replace the fasteners of the same specification.

3. When the basketball stand needs to be cleaned, use a neutral detergent to avoid damaging the protective plastic layer.

V. Transportation and storage

The basketball stand should be handled with care, and should be prevented from bumping and rain during transportation. The storage place should be ventilated, dry, and moisture-proof.